Technology

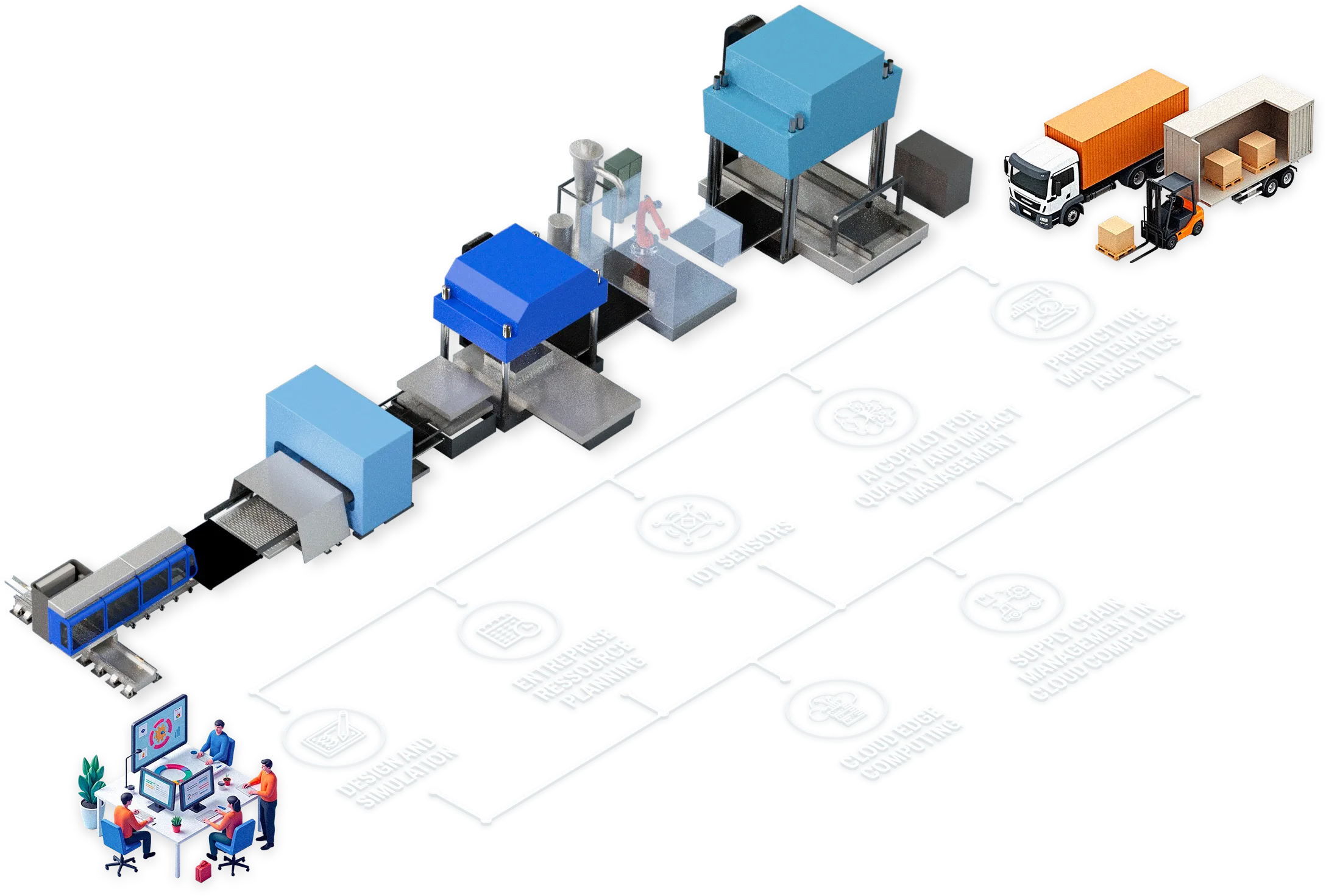

At Artemis Composites we use robust, automated processes to reduce the impact of transport with lightweight, structural composite parts. Our sustainable and digitally-integrated process leads to reduced waste and cost while producing repeatable, high-performance products.

Technology overview

Smart solutions,

proven processes

We have drawn on decades of innovation to produce a scalable, industrial manufacturing system. Combining established composite processes with state-of-the-art digital automation, our solution is cost-effective and sustainable.

Process and materials

Stitched together

with innovation

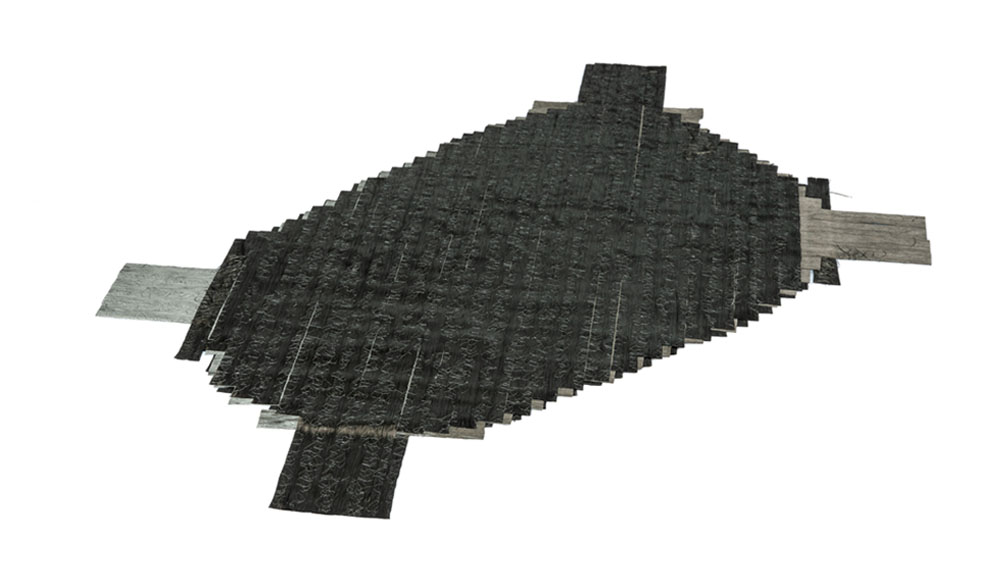

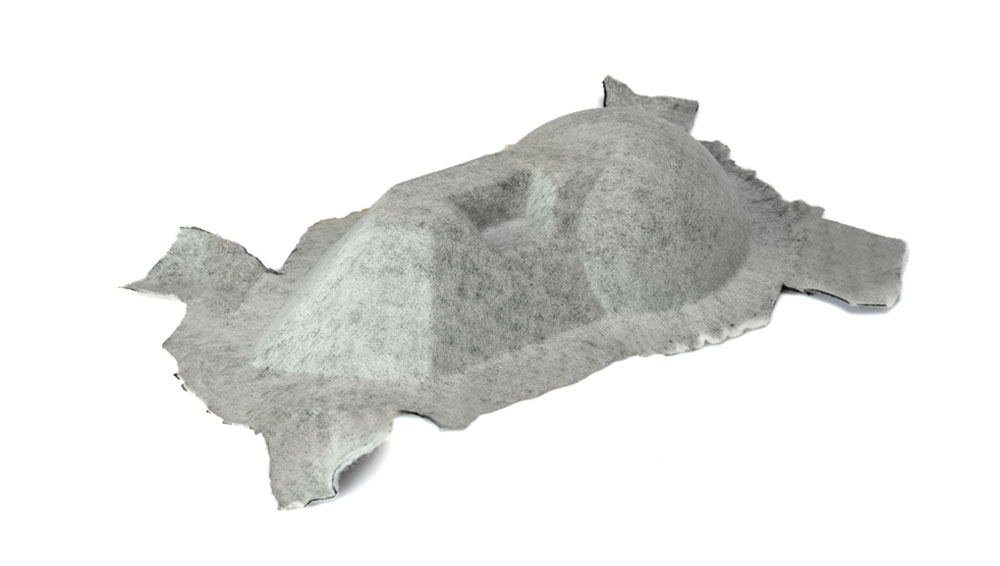

To make these processes compatible, we invented Crossfelt® – a disruptive innovation, entirely new to the composite world.

Fibres from a short fibre felt are inserted through the thickness of the 2D ply layup, linking from the top to the bottom. This keeps the plies in position and wrinkle-free through production and increases resin flow while offering mechanical, aesthetic and functional advantages.

Crossfelt® makes repeatable, automated high-rate processing achievable with high-performance composites due to several advantages compared to fabric, or automated fibre placement without Crossfelt®:

- Fibre movements are well distributed in the 3D forming process, avoiding local gaps and wrinkles

- Preforms are robust and stiff, so easy to manipulate robotically, rather than floppy and susceptible to damage

- Preforms can be trimmed with high accuracy, without fibre dust or fraying edges

- Resin flow is greatly improved as the Crossfelt® fibres introduce flow paths through the stack

- The felt creates an excellent surface finish, removing problems of fibre print-through or resin-rich areas

Advanced automation, established expertise

The result is a unique and reliable production line offering economic and technical performance to produce high quality structural composite parts at the rate you need.

The advantages of Crossfelt® technology

Crossfelt® makes repeatable, automated high-rate processing achievable with high-performance composites due to several advantages compared to fabric, or automated fibre placement:

A new composite material is born

Crossfelt® technology opens up a new world of opportunities in composite applications.

The Z direction fibres bring a truly 3D material architecture leading to inherently better properties.

Mechanical properties

Through fibres deliver improved impact properties and delamination behaviour without loss of in plane properties.

Enhanced surface finish

The well distributed Z fibres limit ply movement and, combined with the fine felt, provide a smooth surface of both preform and part.

Multi-functional

Different fibre types can be used to manage electrical conductivity or insulation, abrasion enhancement and other smart properties.

Digital design

Fully digital design for manufacture

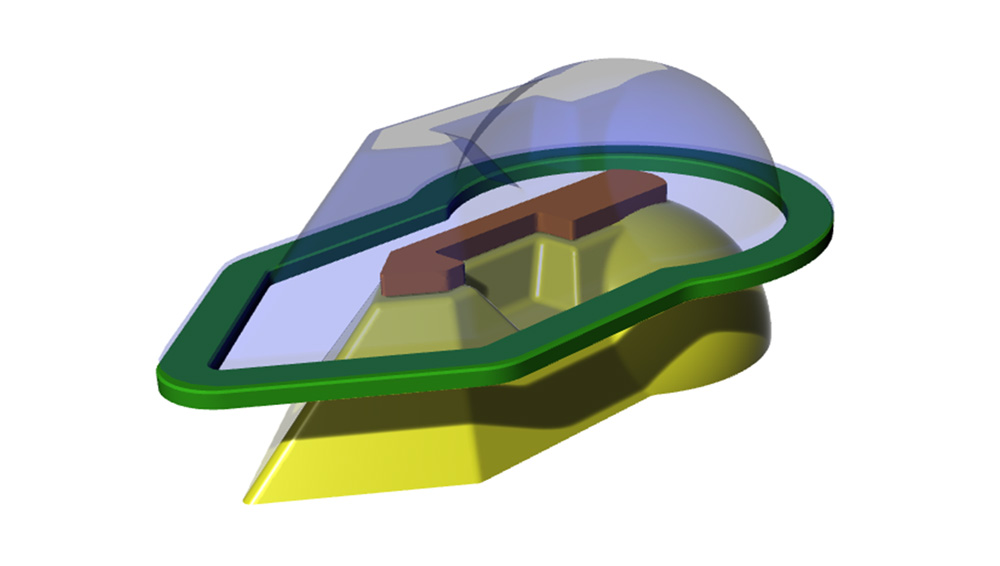

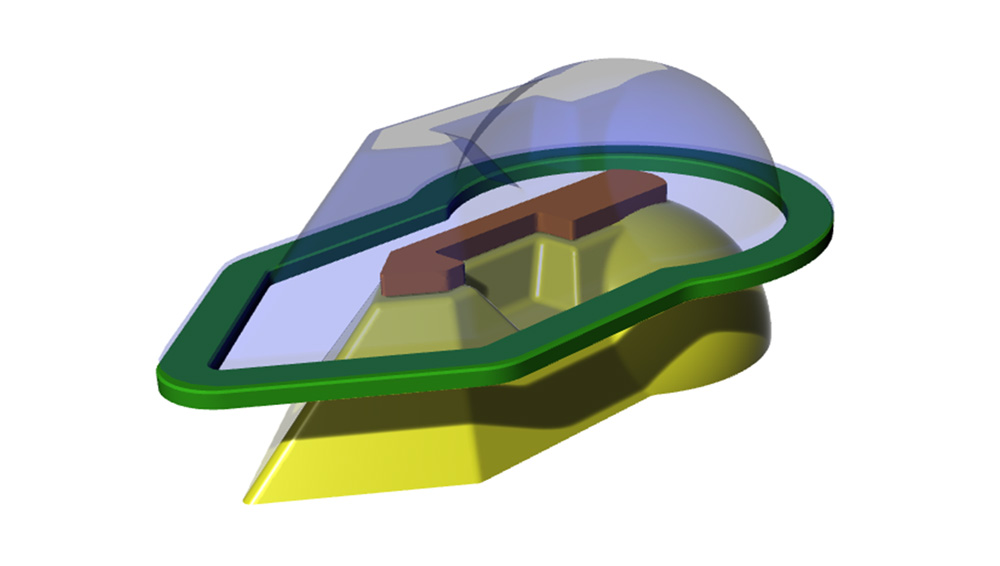

Beginning with your CAD model, we can optimise your 3D part design so the fibres follow the main load paths, minimising weight.

Simulation of both the automated fibre placement and stamping processes means that we can set up the forming process sequence to match the FEA model. The model can be exported for validation by the client, with fibre angle and ply thickness on each finite element.

Our proprietary material data card generated for the forming simulation, validated by numerical/physical correlation guarantee that the produced part accurately matches the one which has been simulated.

Quality monitoring

Consistent, tracked products – every time

Our digitally integrated design and production system, combined with client support, ensures exceptional control over our products. The fully automated production line has been designed in order to respect the highest quality standards defined by the aerospace and automotive sectors, and is operated and maintained by highly qualified staff.

Full digital monitoring and data collection provides traceability through each production step and optimises and energy efficiency. The data feeds into our IoT platform to deliver exceptional quality management according to relevant standards.

Laser measurement techniques verify manufactured part geometry to tight tolerances and non-destructive testing is used to establish mechanical integrity.

Any drift in the automated production line is anticipated due to continuous analysis of key indicators to guarantee productivity and quality. Enabled by our IoT platform, we utilise mixed reality – integrating physical and virtual products – to enhance service in real time. This is combined with predictive maintenance algorithms to anticipate servicing requirements and avoid costs associated with unscheduled downtime while extending the lifespan of equipment.

The result is a highly repeatable process delivering consistent, cost-effective products at scale.

Applications

Proven solutions for

the aerospace and

automotive industries

Aeronautics: lighter structures, greater strength, compliance with strict standards. Automotive: Weight reduction, flexible design, large-scale production.