Products

From concept design through to serial production, Artemis Composites works together with the customer to create high-performance, cost-effective parts. Our extensive experience and ongoing research is coupled with a suite of design and simulation software tools and state-of-the-art equipment to realise and optimise your ideas. A dedicated development line and testing capability means that we can support your part development and qualification process to accelerate time to market without disrupting production.

Part

production

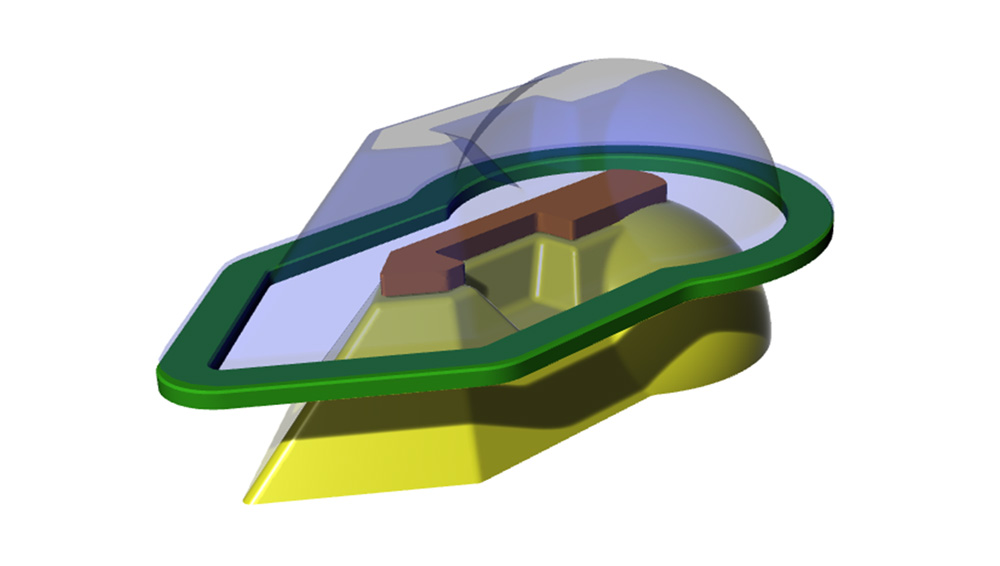

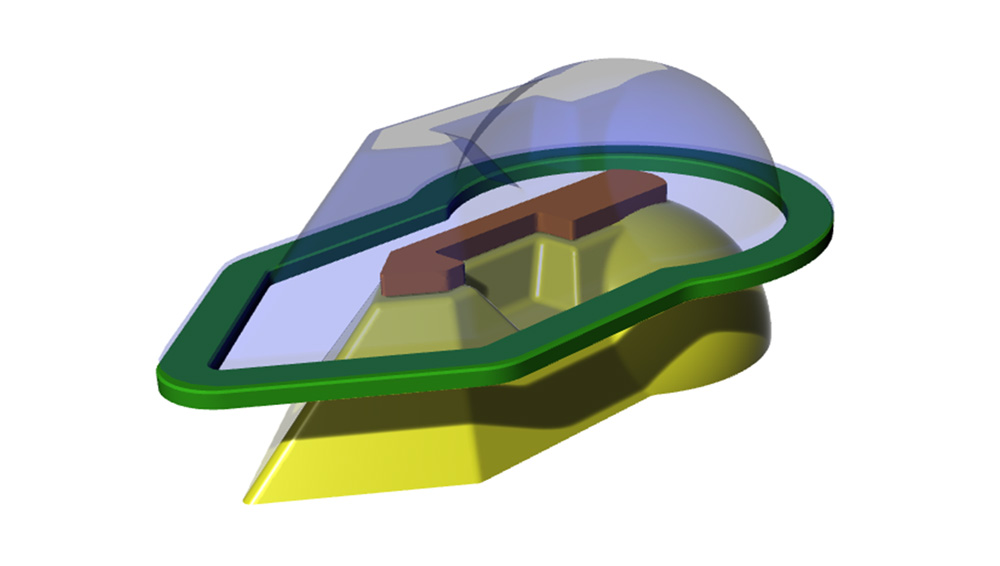

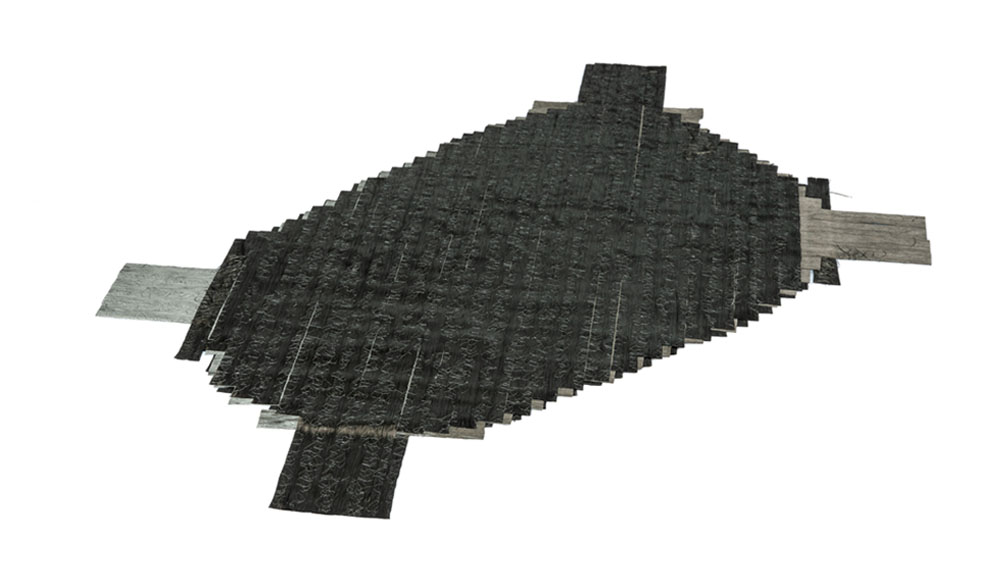

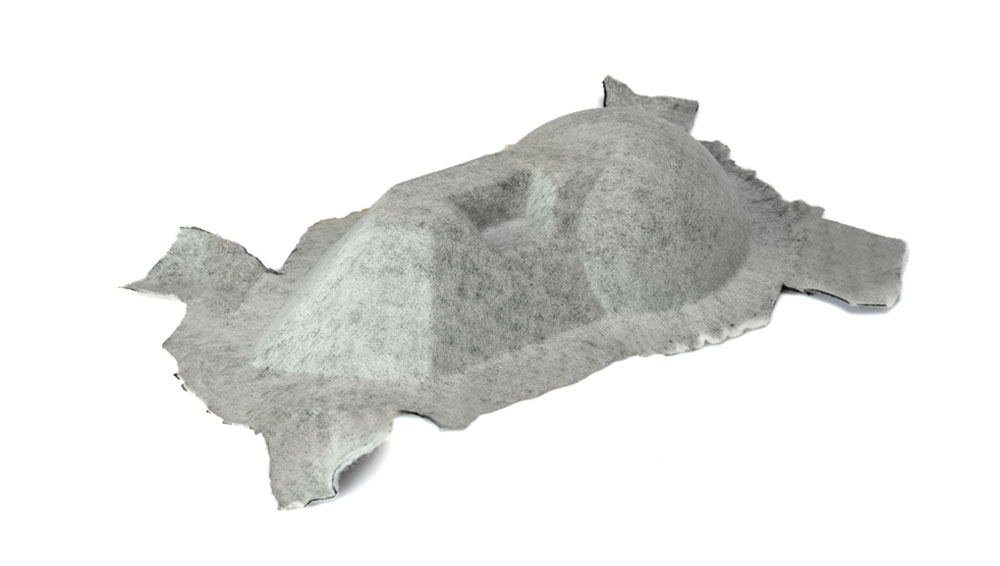

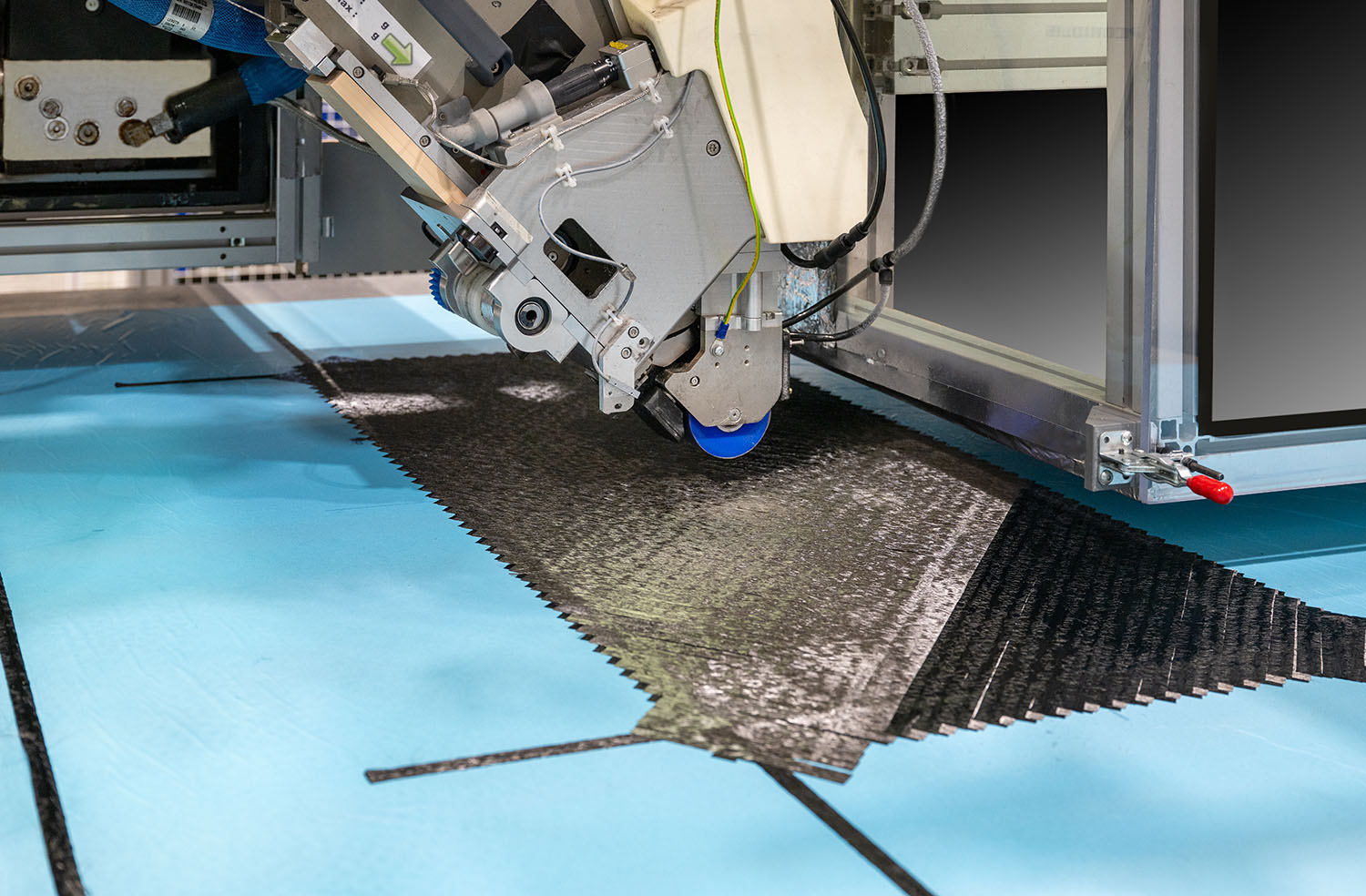

Our unique Crossfelt® technology enables robust, automated processes to work together with full digital simulation and tracking. The result is a unique and reliable production line offering economic and technical performance to produce high quality structural composite parts at high rate.

Process and materials

Part Development

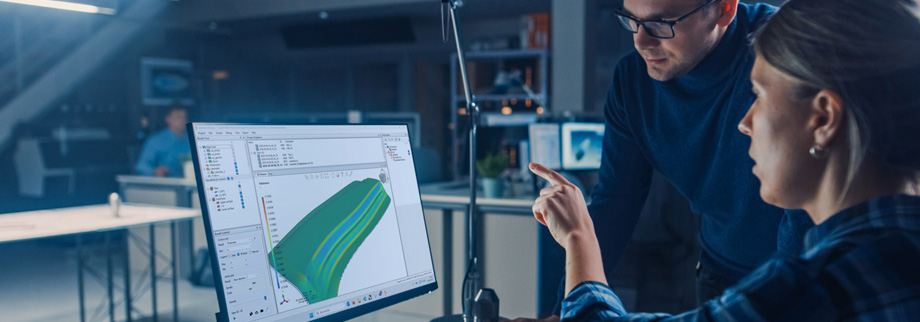

Our team’s expertise in composite design and processing spans the capability needed across the whole part development and qualification / verification process. With a dedicated production line for development, we provide a fully digital design and process simulation (digital twin) that secures not only the part performance but also verified production quality at rate.

Our full suite of services includes:

Product concept and design

- Co-engineering and validation of requirements with client

- Design, simulation and analysis software

- Streamlined LCA

Process engineering

- Material selection

- Tooling design

- Process design, simulation and verification

- Costing

Prototypes and testing

- Samples, pre-series for verification

- Metrology

- Testing with partners:

- mechanical,

- non-destructive testing,

- lightning strike

Project management

- Coordinated service from concept to qualification

- Tracking through Technology Readiness Levels

- Material sourcing

- Tool sourcing

- Logistics

Part Development

Development capability and equipment:

Our dedicated part development line can produce parts up to 1.7 x 1.2m with:

- 1 x ½” automated fibre placement (AFP) machine

- Crossfelt® functionalisation of 2D stack: up to 1.2m width

- Preforming press: 1 tonne, 0.8 x 0.8 m

At partner company:

- 1500 tonne HP-RTM press

- 6 axis water jet trimming robot

- Dimensional control

- Non-destructive testing (ultrasound, thermography, X-ray/CT)

Part

Production

The combination of our excellence in AFP, our unique Crossfelt® technology and our digitally-integrated composite manufacturing process means that we can produce optimised parts at high volume. With the ability to produce parts at rates of up to one per minute while maintaining consistently high quality, we ensure uninterrupted production.

Production capability and equipment:

Our automated production line will produce parts up to 2 x 2 m with:

- 16 x ½” automated fibre placement (AFP) machine

- Crossfelt® functionalisation of 2D stack

At partner company:

- Preforming press: 350 tonne, 2 x 2 m

- Preform heating area and automated transfer

- 6 axis water jet trimming robot

- 6 axis transfer robot of preforms or parts between the different processes

- HP-RTM injection unit and 350 tonne press

- Ply location and fibre orientation control

- Dimensional control

- Non-destructive testing (ultrasound, thermography, X-ray/CT)

Material options

Material options for development and production equipment

Automated fibre placement (AFP)

- Fibre width spreading and calibration to ½” width

- Binder: Proprietary non-reactive epoxy-based binder, compatible with aero & auto epoxy resins

- Ply aerial weight 100 to 300 gsm

- Minimum fibre length: 100 mm

AFP fibre types supported:

- Direct carbon fibre 24K and 48K

- Glass fibre roving

- Natural fibres (flax, hemp)

Crossfelt® functionalisation of 2D stack:

- Proprietary felt: PAN, polyester, aramid, recycled carbon, metallic, glass fibre

Certifications

we’re working

towards

Quality and environmental management contribute to reducing scrap, saving energy and maintaining a cost-effective product and we want to demonstrate that our social and environmental commitments are robust, well-founded and transparently tracked.

We are working towards the following certifications:

Applications

Proven solutions for

the aerospace and

automotive industries

Aeronautics: lighter structures, greater strength, compliance with strict standards. Automotive: Weight reduction, flexible design, large-scale production.