Audi

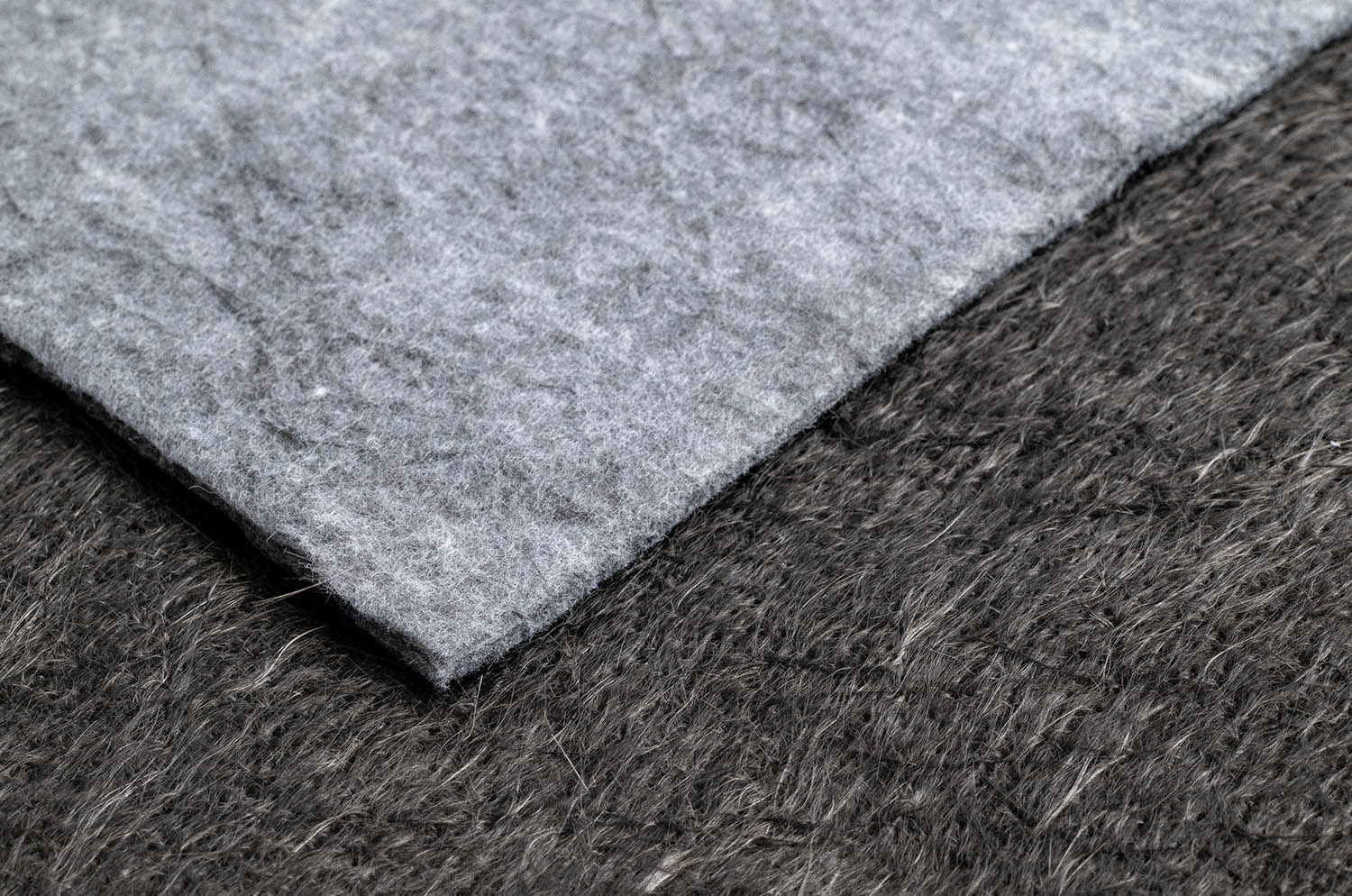

A research project funded by the German government, with Audi as the end user, looked at reducing vehicle weight to lower emissions. Several parts were produced using Crossfelt® technology as an alternative to conventional composite processes such as bindered fibre and non-crimp fabric.

The mechanical performance and key advantages of this technology, including reduction of scrap and rework, reliability, and improved productivity, were successfully validated, along with cost estimates.